Lowest Fuel Consumption

Lowest Maintenance costs among

Burners and Longest Life

The design & components used allow for least breakdown situations.

Lowest Fuel Consumption:

The only European design Burner in India. At least, 10-15% less Fuel

Consumption compared to other Pellet Burners available due to high

efficiency of more than 90%.

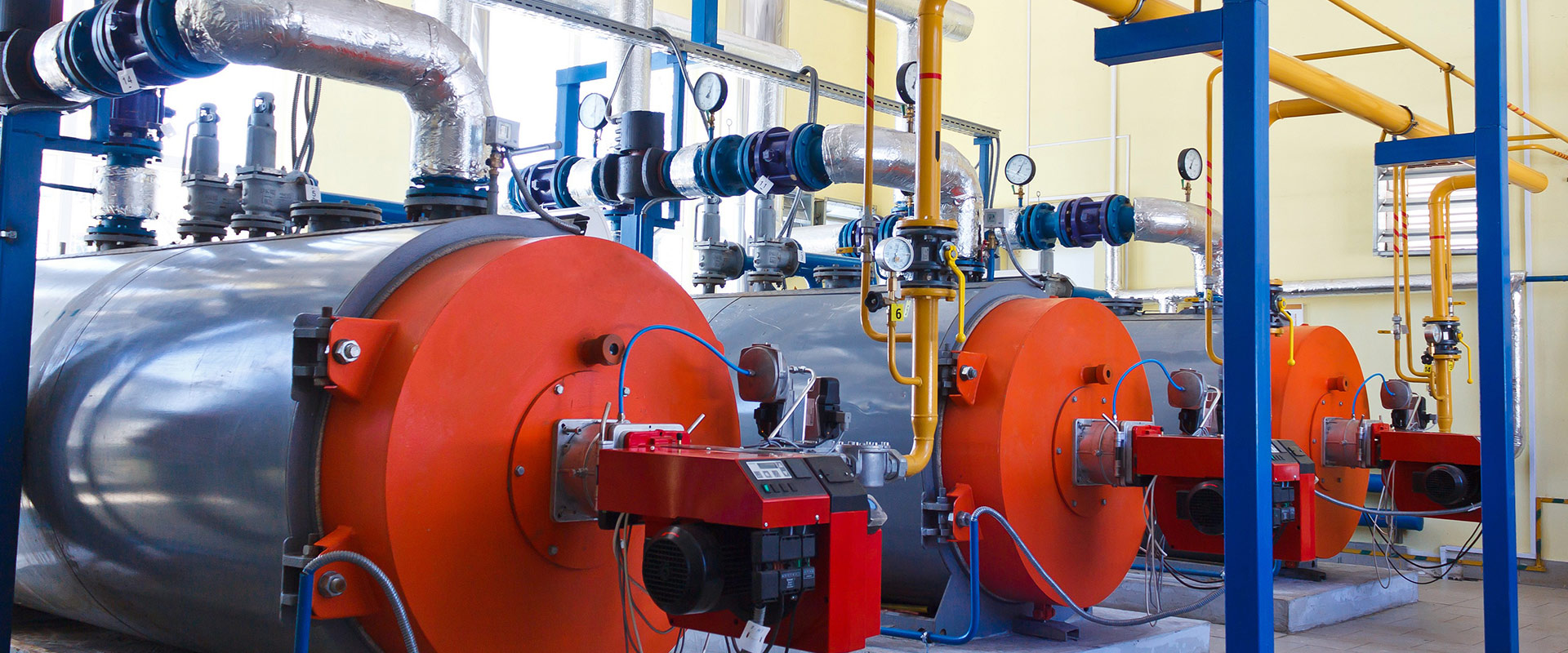

About Pellet Burners

We have Burners of capacities varying from 1

lakh Kcal / hr. to 8 lakh Kcal / hr.

Economics of using Pellets

Diesel is 8500 kcal/liter of energy and Pellets about 4300kcal/kg so about 1:2

ratio. Energy equivalent price of Pellets is about R. 30/kg. So if cost of

Pellets is about Rs.15/kg user is reducing cost by about 60%.

We can set up a new Pellet Burner system, or we can retrofit in quick

time and replace existing Diesel Burner system.

Applications:

Like any other burner, biomass pellet burner is applicable in big industries as

well as small-scale industries. For example, it can be seen used in food

industries, Textile Industries, Metal Industries, Packaging, Plastic Making

Industries, etc.

How pellets are cost effective

| Particulars | Pellets(kg) | PNG(m3) | Diesel(ltr) |

|---|---|---|---|

| Calorific value (kcal/unit) | 4200 | >9000 | >9100 |

| Rate (per unit) | ₹15* | ₹70* | ₹90* |

| Equivalent pellets consumption (per unit) | 1kg | 2.5kg | 2.5kg |

| Cost of pellets | ₹38 | ₹38 | |

| Saving | ₹32 | ₹52 | |

| Saving | 46% | 58%% |

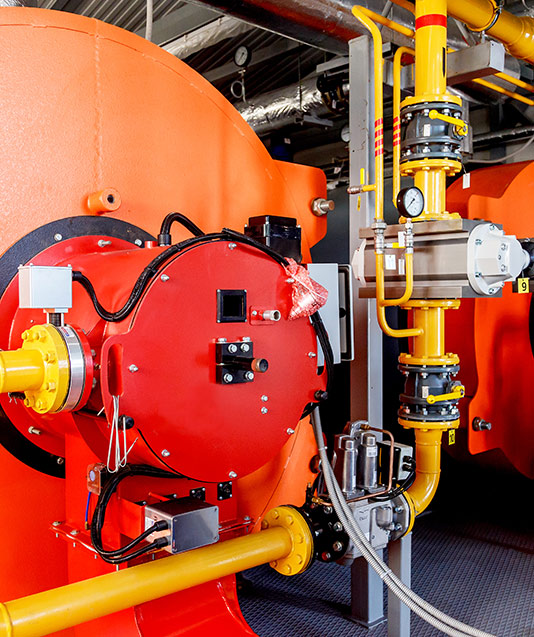

WOOD PELLET FIRED BURNER FEATURES:

- WE INSTALL WOOD PELLET FIRED BURNER WITH FOLLOWING FEATURES: .

- • Specially Designed for continuous industrial operation.

- • Eco friendly combustion.

- • Very low Sox-Nox which completely under limit of pollution control board.

- • Lower cost of fuel compared to Oil (HSD/LDO/FO) & Gas (LPG/PNG/CNG/Propane).

- • Minimum guaranteed 30 to 50% savings in fuel cost.

- • Easy to store, Handle, Transport of pellets.

- • Auto adjusting modulating firing mode based on feedback of process temp/pressure.

- • Provision of additional Manual mode operation in the case if PLC fails.

- • Storage Silo provision for one shift fuel storage & to avoid frequent re-fueling.

- • Equal quality, un- interrupted availability of pellets, all the seasons.

- • Very small ash content as residue after burning i.e. below 3-5%.

- • Highly efficient (90-95%) controlled combustion with PLC controlled elect panel.

- • Low power consumption.

- • Clean & Silent operation.

- • Compact sized installation compare to Wood Gasifier system.

- • Very few modification is required to replace existing Oil & Gas burner.

- • Highest range of capacity available in India.